Whether professional from the world of construction or simply a fanatic of masonry or do-it yourself projects, one thing every specialty workman must have in his toolkit is the right set of tools. One of such must-have tools is the 25mm core bit—an impressively high-quality core drilled attachment that gives you the freedom to drill unambiguously precise holes through several materials. The 25mm-drill bit being very minute has a cheery tip that can quickly go through materials such as concrete, brick, and stone and will also machete some types of metals. This hole saw has gained unrivaled popularity, simple because this is your go-to most-often-used tool and bitchers, let it be known. If thus I’ve just told you all about how important the 25mm core bit is, what will subsequently be a central part of your toolkit and come back to others through the selection and effective guidelines on proper use, do we need an application or examples of current practices in modern construction?

Why Your 25mm Core Bit May Be Important to Have Right Now? Maybe there is no ideal size, but when it comes to 25mm diameter, we can indeed talk about the Goldilocks size of core bits. In fact, that is not an exactly small or oversized core but certainly a bit ready for the majority of applications, from installing electrical conduits, plumbing, and anchoring systems to venting holes. The fields where is may be used include extremely various numerous industries, from those busy constructions wherein people are slaughtering work and you don’t want them to match-damage everything to home remodeling. In that case, drilling is required too, but because it creates clean and smooth slots, workers can wound-up, so do their work more rapidly. How to Pick the Right 25mm Core Bit for the Job? The perfect scenario of a 25mm core bit is always result in an ideal situation and some outcomes of quantity and also several “qualities” you can choose. First, you should always make sure the pitching works with what you are drilling, obviously concrete or brick but metals for example. When it comes to a connection with a drill, it should have the right shank to fit in, whereas notches should be measured, particularly for the cutting teeth: points are smoothed with a continuous drill and segmented cutters work best on abrasive materials. The quality should always also play the most important role where brands like dec touch is obviously a recognizable and durable brand that will last you ages. Eventually, you should also always consider whether to wet drill, which is easier fog-free drilling and life prolonging, some bit perfect fits; the other ones are ideal for highly accurate drilling applications. Hence, that is the way you pick the right 25mm core bit for the job!

What it boils down to in order get the most out of your purchase for a 25mm core bit is its proper utilization. Use the appropriate mandrel and drill according to guidelines for safe drilling; do not force into overheating or premature wear. For wet drilling applications, the constant flow of water cools the bit and loses fine material. Consider replacing the bit if it becomes damaged. Care of the bit after drilling like wire brush cleansing and storage etc. A proper RPM set for the material to be drilled unlike, will help in preventing overheating back again reducing time within drill down

Aligning electrical fittings safely,without causing any damage to the existing installations for channeling wires or tubing.

Plumbing Work - Creating ducts for pipes and fixtures maintaining the ability of a building to carry structural loads.

In closing I think this small 25mm core bit was a fair mix away of "good things come in little packgages. In addition to its compact size, the impact of performance this tool can deliver crosses industries. Use the best bit for your job, maintain it well and this essential component of construction equipment is going to be one that you are sure to appreciate its addition time after time.

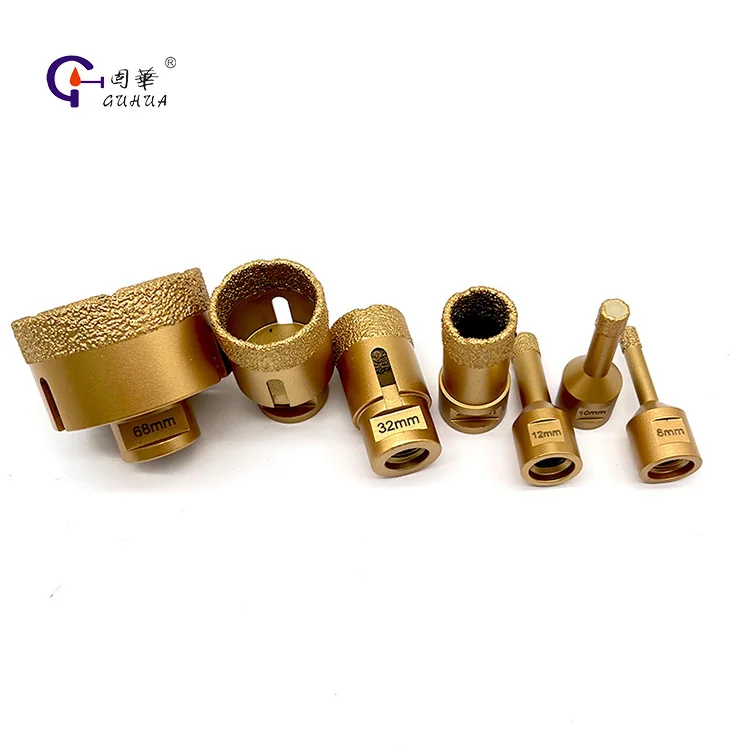

It is the unique construction of a 25mm core bit that makes it so powerful, often containing a tungsten carbide tip with steel tubing. The helical shape of the cutting edge is such that it cuts a cylindrical core sample out of the material beind drilled, as opposed to grinding away slivers over time like traditional twist drills. This means cleaner, more accurate holes with less susceptibility to surface marring or fracturing. Its small diameter also allows for drilling where other, more bulky machinery would not fit as well, and its thin width reduces waste of material due to separating out-of-spec diameters during manufacturing- this efficiency makes the hole saw a compact and economical solution to punching or rotating holes.

This 25mm diameter is often the 'Goldilocks' size in core bits – not too big, not too small but just right for many situations. And it makes for an excellent option in many applications such as installing electrical conduits, plumbing pipes anchoring systems, or venting holes. It can work in many industries: from busy construction sites to home remodeling, where drilling is needed and you do not want it-match damage. And the ability to cleanly and smoothly make slits makes work quick- so that, busy workers finish their jobs quickly.

Since the choice of 25mm core bit should always be ideal, a range quantity of certain aspects are there for you to consider. The first thing to do is make sure the pitching mechanism will work with what you are drilling, concrete or brick and even metals. When choosing the bit, ensure it has a shank suitable for your drill and check the cutting teeth − segmented bits are best used on abrasive materials; continuous cutters deliver smoother results. The qualtity is very important, hence it if from a recognized brand name will indeed be durable and could potentially last ages. Finally, think about whether or not you need to wet drill: while drilling may be required without creating fog and prolong the life of blades, some are ideal for accurate drilling applications.

Ensuring the Long Life of Your Core Bits 25mm in Size

The key to get the most out of your 25mm core bit purchase, comes down proper usage. Keep safe by using adequate equipment, and exercising a controlled-pressure drill; avoid overheating due to high pressure or early wear. Use a steady stream of water to cool the bit and carry out fine material on wet drilling applications. Check the bit occasionally, if there is a damage replace it. The longevity of the bit can be extended by taking good care, post-drilling like cleaning it with wire brush and storage etc. Keep in mind, using the correct RPM setting for the material being drilled will help prevent overheating and reduce drilling time.

Electrical Fittings: For channeling wires or tubing accurately and without any damage to the existing installations.

Plumbing Work - Making holes for pipes and fixtures keeping their structural capabilities intact.

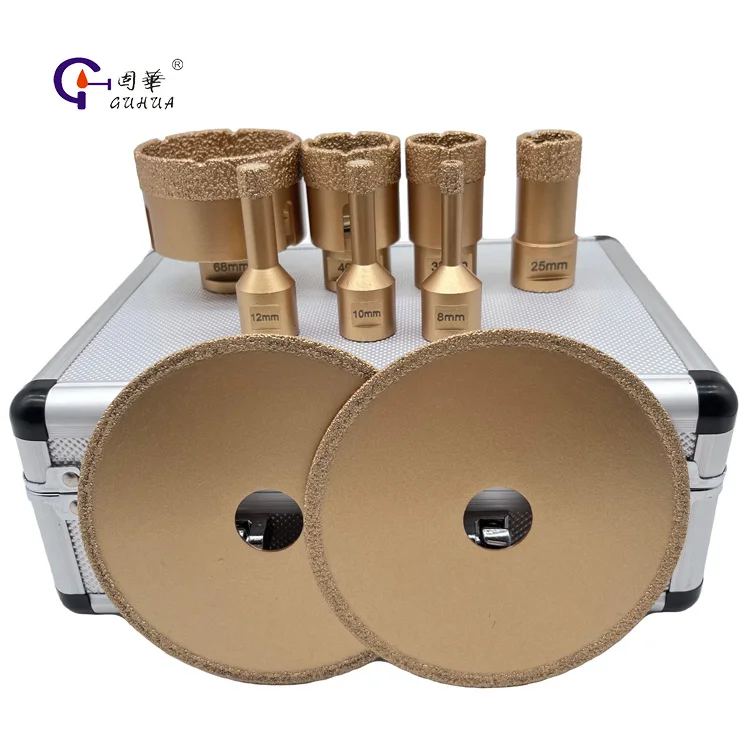

Guhua is professional R D team composed top engineers and experts who have been deeply involved in industry for over 20 years. We obtained 40+ invention patents, we are the world leader in designing, developing 25mm core bitbrazed diamond instruments, enabling deep customized drilling, cutting and grinding machines for processing various hard brittle substances as well as intricate high-precision products.

We've been business 25mm core bitfor over 20 years. have clients across more than 60 countries. have local offices and subsidiary stores in the UK and also India and Kenya. are able to provide a single-stop solution our global customers ranging starting from R D and production logistics and after-sales service.

are able provide products high quality outstanding cost performance thanks to 25mm core bitproduction processes.

25mm core bitproduction experience has helped us develop strict Q C standards. products thoroughly tested prior shipment, which includes random inspection each process quality control each of major procedures. SGS certification testing and international ISO09001 quality management system both obtained. All Guhua products are backed by MPA and CE Safety certifications.

HVAC and Ventilation: It allows you to cut accurate holes needed for Heating, Air conditioning or exhaust solutions.

Concrete Cores: An example of taking a sample for testing (in the construction and engineering fields).

So, in conclusion I thought this small 25mm core bit was a decent combination of "good things come in small packages. And besides its relatively small stature, this tool packs an enormous punch and can take on a plethora of jobs within any number of industries. Choose the right bit for your project, use it properly and treat it with respect to get the most out of this key piece of construction equipment in a way that will make you thankful you added an auger drill bit to your gear.

Our professional sales team are waiting for your consultation.

Copyright © Nanjing Guhua Electromechanical Technology Co., Ltd. All Rights Reserved | Privacy Policy