Therefore, in this perspective a diamond grinding wheel for granite surfaces is required to operate with the granite. Its exceptional construction facilitates its use in cutting, modeling and grinding on granite. The wheel- this is referred to as due to diamonds being stored throughout its abrasive face in the diamond particles so that it has a grinding surface and lifetime.

Benefits of using Diamond Grinding Wheel for Granite-thebigbanglaunch - How does it leave a smoother and almost polished surface except the unsightly scratsches that will be there after you use our traditional grinding wheels?...-These perfect DIAMOND GRINDING WHEEL FORGETE work with so much strength, but they hold off especially when compared to some even better. Secondly, they have very low dust production meaning that at workplaces they are safe and provide global environmental salvation as well.

For years, manufacturers have been working to make diamond grinding wheels for granite better The new ways have made these wheels efficient and given them a long life sentence. The wheels are actually beefed up, thanks in large part to a new "Hybrid Bond Formula" combining resin and metal bonds that is claimed by Konig's techs to make them stronger. It is also uses to smooth cutting and grinding withi segment sideaces,

If you are looking for ways to use a diamond grinding wheel kindly follow the link How is Diamond Grinding Wheel Made and in which way it helps?

When looking at the diamond grinding wheel for granite, these are some must-have. Remember to wear protective equipment - like safety glasses and gloves. At first, we should clean the granite surface totally a create scratch-less then again it may cause dirt or dust will damage your tool. Once the surface is prepared, consider how heavy the tool is and at what speed you are trying to break. Slowly start it and do so in a smooth, steady movement with even pressure all the way through. Three, water-cooled/sugar wheel - and quench that hotness.

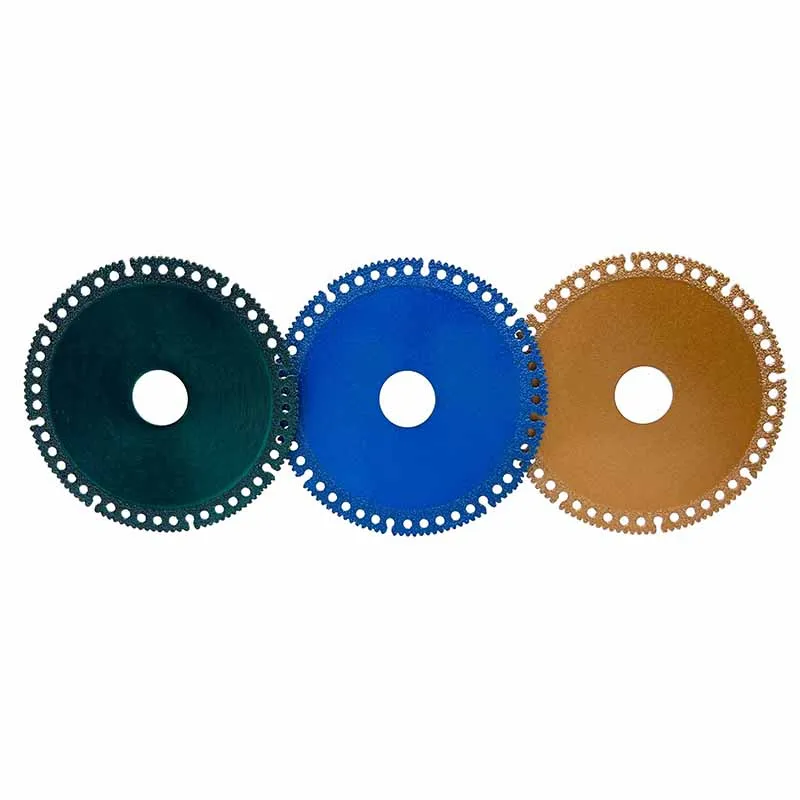

Make sure to use a diamond grinding wheel appropriate for your machinery. Diamonds in premium wheels tend to be higher diamond content and are designed for heavy grinding, with slower wear. They are useful tools that you can use in grinding, shaping and polishing granite countertops as well sinks & other decorative items.

So that all was about diamond grinding wheels for granite summary. This constant dishwasher is so good in terms of cutting or polishing the surface that you can pretty much cut it into any shape to get your desired finish. One of the investments that is made with compatibility and qualityThe selection criteria for a diamond grinding wheel can vary, depending on; each id different from others an evolution in manufacturing continues. If safety protocols are not strictly adhered to, the benefits of this tool will be diminished.

What Are The Benefits Of Using Diamond Grinding Wheel For Granite It leaves a smooth and almost polished surface without the unsightly scratches which are left behind by conventional grinding wheels. - Additionally, these same wheels are much more durable and will last longer than some of the best out there. Furthermore, their dust generation is very low, making them safe at the workplace and global environmental rescue.

Over the years, manufacturers have been determined to improve diamond grinding wheels for granite. These wheels are efficient and have a longer life because of the new methods being used. The wheels do get stronger, largely due to the addition of so-called hybrid bond formula that combines resin and metal bonds, making them more reliable. It is also being used to smooth cutting and grinding along with the implementation of segmented edges.

These are must-have when it comes to diamond grinding wheel for granite. Always wear protective gear including safety glasses and gloves. First of all, we need to make sure that the granite surface is as clean as possible and not too dusty or covered in dirt which might harm your tool. After preparing the surface, consider how heavy the tool is and at what speed you want to go. Just start slow, and do it smooth and steady with even pressure throughout the whole thing. Finally, use water or cool the wheel down to avoid getting heat.

Diamond grinding wheel suitable for your specific machinery is essential to use. Premium wheels have a high diamond content and are designed to stand up the rigors of heavy grinding without excessive wear. These handy gadgets have uses in the performance of grinding, shaping and polishing granite countertops as well sinks, decorative items.

This is all a summary of diamond grinding wheels for granite.A good quality, the constant dishwasher can be cut into any shape you wish to achieve your ideal finish when it comes to straight-out cutting or polishing the surface. Given the ongoing evolution in manufacturing, a diamond grinding wheel is no exception to that list and when choosing one investment along with compatibility as well as quality must be taken into account. This tool requires strict compliance with safety protocols in order to maximize outcomes.

have over 20 years of diamond grinding wheel for graniteexperience clients from over 60 diamond grinding wheel for granite. have subsidiaries and local warehouses the UK, India, and Kenya. We offer a one-stop solution our global customers starting from R D to production and logistics to after-sales services.

are able provide products high quality outstanding cost performance thanks to diamond grinding wheel for graniteproduction processes.

developed strict Q C standards based years production experience. All of our products tested thoroughly prior to delivery, and include random inspection each process and quality control for every component of the key procedures. SGS certification for diamond grinding wheel for graniteand the international quality management system ISO09001 are both achieved. Each of the Guhua products are backed by MPA and CE safety certification.

Guhua's R D team comprised of experts engineers who have more than 20 years experience in the industry. have 40+ inventions patents, and we are market leader for developing, designing and manufacturing brazed tools. This lets diamond grinding wheel for granitedeeply customized tools that are used work with various hard materials such as brittle ones as well as complex high-precision products.

Our professional sales team are waiting for your consultation.

Copyright © Nanjing Guhua Electromechanical Technology Co., Ltd. All Rights Reserved | Privacy Policy