Concrete is a powerful substance in buildings. But punching holes through concrete can be tough. That’s where the dry coring comes in handy! Dry coring employs a specific drill bit that does not require water, or any other liquid. So drilling becomes much cleaner and higher speed than usual.

One of the top reasons that dry coring stands out is that it saves time during construction. Because dry coring doesn’t require water, the concrete won’t have to dry after it’s been drilled. This speeds up construction, which is cheaper and faster. And since dry coring doesn’t leave a big mess the way traditional drilling does, there’s less mess to clean up in the end, making it all that much more efficient.

Using Dry Core for Plumbing or Electrical A home owner or do it yourself professional can easily remove the center core of a concrete block to make for plumbing pipes or electrical wires using a cold chisel and a maul and or any type of brick punch.

Dry coring isn’t just about making holes in concrete. One can also use the machine for plumbing and electrical jobs. The size and shape of holes is important when installing pipes or wires. By dry coring, you can create more accurate holes, and that’s perfect for this type of jobs. And because it’s clean, there is less risk of damaging pipes or wires while drilling, which makes it a safer bet for plumbing and electrical work.

The dry coring is a valuable tool as it may work on a variety of materials. In addition to concrete, it can be used on materials such as brick, stone and even asphalt. This feature makes it a versatile tool for various construction jobs. Are you constructing a building or road, or even laying a sidewalk?

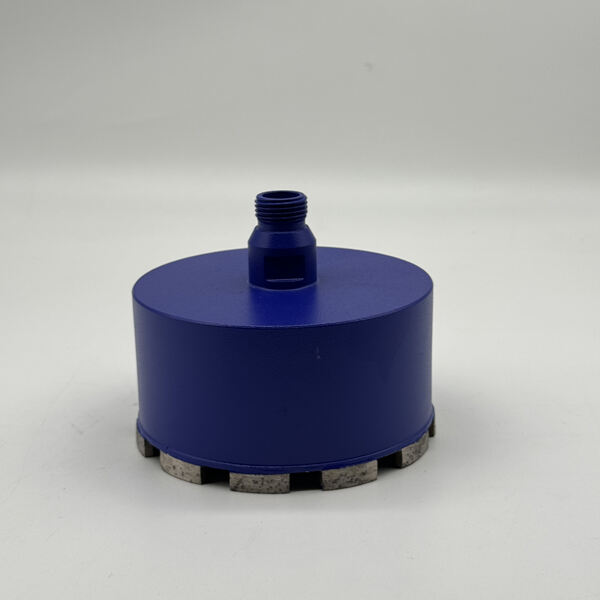

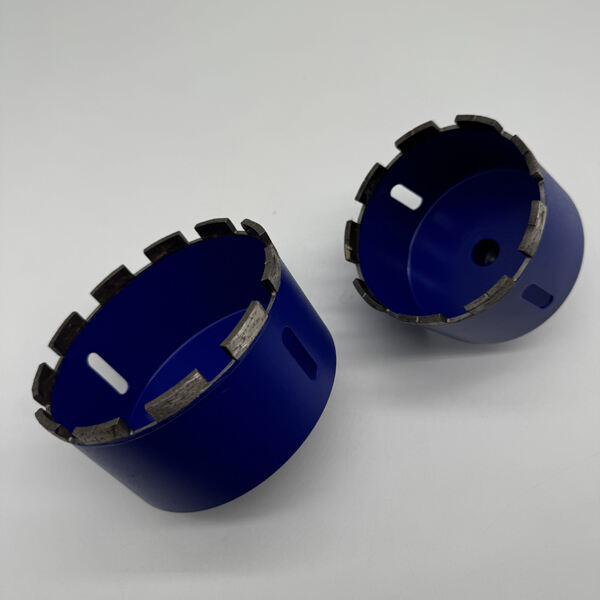

Keep the following in mind when you wish to choose the best dry coring gear. First, consider the size and kind of hole you want. One job might require a certain type of drill bit, so make sure you have that one. Also consider the torque and revolutions per minute, or speed, of the drill, and any features that could be beneficial for your project. With the proper equipment, you can ensure your project is fast and successful.

Guhua's R D team consists experts and engineers, with over 20 years Dry coringin field. Guhua has over 40 inventions patents are the leading company in field for developing, designing and manufacturing brazed tools. This lets us create deeply customized tools that are used to treat a variety materials which include brittle materials, as well as more complex, high-precision items.

With more than 30,000 square metres factory space, modern equipment, efficient Dry coringlines, we're able assure quick responses to orders provide high-quality products that cost-effective to our global clients through efficient processes for production and stringent Q C guidelines.

extensive production Dry coringhas led us create rigorous Q C standards. products are strictly tested prior delivery, and include random inspection each process as well as quality inspections every component of key procedures. We've obtained SGS testing certification international ISO 9001:2015 quality management system certification and all Guhua products are MPA and CE safe.

We've been operating internationally over 20 years. We have clients more than 60 different countries. have local offices and Dry coringstores in UK as well as India as well as Kenya. are able to provide a single-stop solution for our global customers ranging from R D as well as production to logistics service after sales.

Our professional sales team are waiting for your consultation.

Copyright © Nanjing Guhua Electromechanical Technology Co., Ltd. All Rights Reserved | Privacy Policy