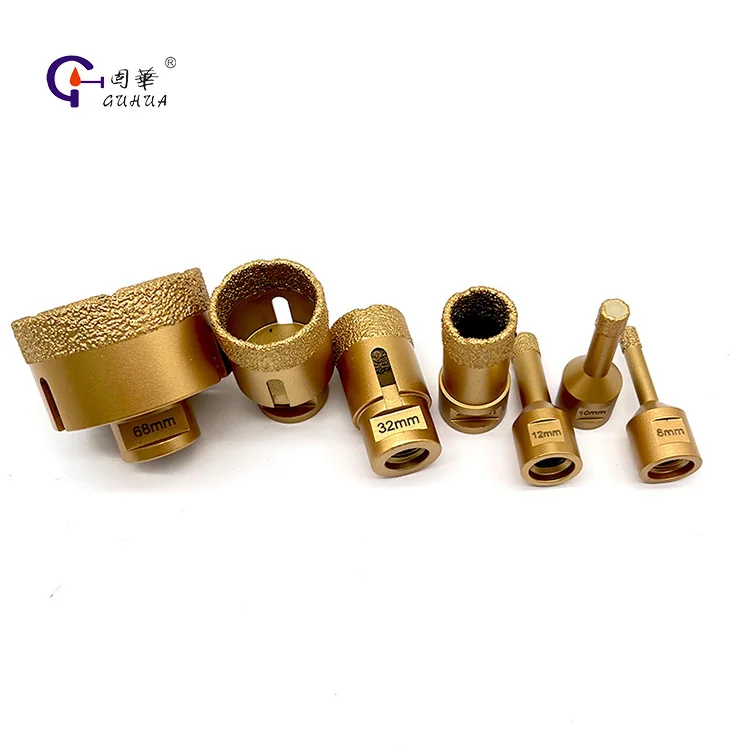

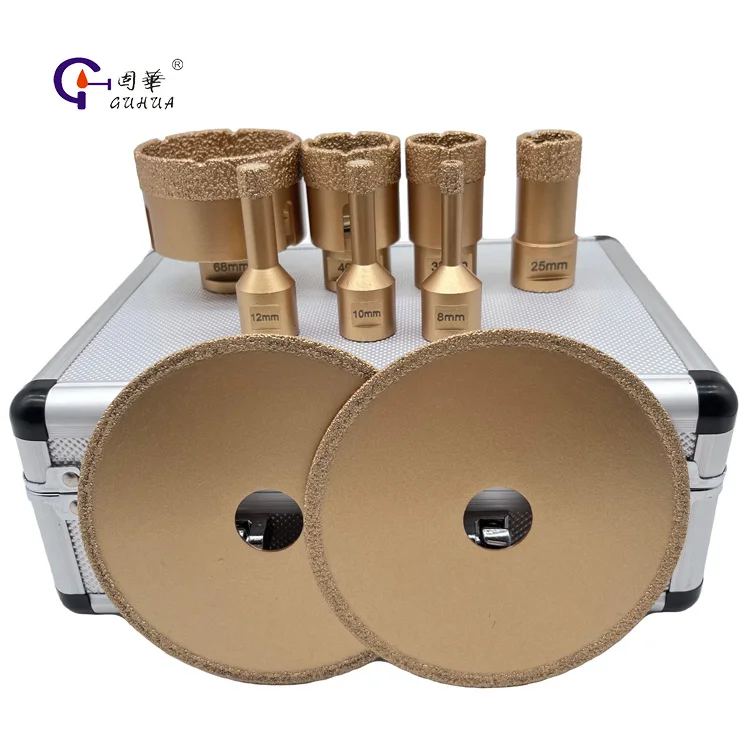

When there is a need for holes, it is hard to imagine doing this in some other elements like wood, stone, or concrete without a hole core bit. This article will go deeper into the matter and help you see just how this tool can maximize work productivity during construction. HOLE CORE BIT STAND OUT Hole core bits are very important for every artisan or operator who is involved in the drilling process. Every power is selling them because they are operating making very accurate holes and do it quickly. In this way, they save a lot of time and thus also lower the cost making them very important tools building sites. From course drilling to tighter drilling projects, hole core bits enable the operator to face incredibly strong materials such as glass, tile, or granite and creating larger holes for piping and cabling. AND TIPS ON HOW TO CHOOSE THE BEST Suitable HOLE CORE BIT It is essential to choose the right for the job hole core bit, which implies what one drills, how large holes need to be, and how quickly on will drill. DRILLER-CUTTER with different levels of diamonds can increase their performance to both durability and cutting strength. Usually, good drillers understand the firmness of the bit that they want to keep in the hole and often put on PPE gear when on a drilling project.

Creating for Efficient Hole Core Bits Innovating Hole core bit tech has come a long way and is constantly getting better and better to make the extremely trying job of producing a clean hole with maximum productivity easier. As soon as they start to dull, many of the modern hole core bits are self-sharpening, lowering substitute rates in the course of drilling. Some even have their cooling systems to extend their lives. At the same time, ensuring the level of sustainability in construction will continue to rise, making environmental hole core bits, which use die fuels or fewer traditional fuels, particularly relevant for their manufacture. Best bit lifespan maintenance practices To guarantee that hole core bits will last for the longest, certain maintenance practices must be followed. After each usage, it should be cleaned with a wire brush and compressed air with the aim of not allowing dirt to accumulate. They must be stored in a cold, clean place free of any danger. They must are checked regularly for chips or cracks, and any broken parts are replaced right away. Careful maintenance may help increase the life of hole core hat and save money on replacements in the long run. .

Limited Final Words on Construction Hole Core Bits So, in limited conclusion hole core bit is a phenomenon that creates precise, neat holes on different materials, unlike any other on the market. With advanced technology and frequent maintenance, this equipment can efficiently and effectively work in the construction industry for a long time. Choosing the right bit is essential to complete construction projects on time, so not underestimate it. In addition, making a modest impression, which expresses its true bezel in the construction industry, it is important to emphasize how important it is in every type of creation.

Hole core bits are essential items in the construction, and every artisan or operator engaged with drilling will attest to this. These drill bits have the power to make clean and accurate holes fast; This saves time in a tremendous way and also reduced the cost so these are very important tools for building sites; From drilling through hard materials such as glass, tile or granite to creating larger boreholes for pipes and cables we can do it all with hole core bits.

TIPS FOR CHOOSING THE BEST HOLE CORE BIT

Selecting the appropriate hole core bit for a particular job is crucial. The decision hinges on factors like the material being drilled, hole size needed and drilling speed desired. Hole Core Bits in different levels of diamond will increase both the durability and cutting speed. Good drillers know how to pick the make of bit they want to leave in the hole and always wear PPE (personal protective equipment) while on a drilling project.

Over the years, hole core bit tech has evolved drastically and is continuously improving in efforts to make producing clean holes with maximum productivity much easier. Modern hole core bits are self-sharpening as they begin to dull, which in turn requires less replacement rates during drilling. A few of the bits have their own cooling systems, to make them last longer. In addition, in order to increase the level of sustainability in construction methods are turning into increasingly more important for producers who also actively develop environmental hole core bits that use less traditional fuels.

To make sure that hole core bits will last for a long time, there are some maintenance practices to follow. It has to be cleaned thoroughly with a wire brush and compressed air after each use in order for it not gather any dirt over time. They need to stored in a cool, dry place and away from hazards for preservation. You will need to check these regularly for any chips or cracks, and replace damaged bits promptly. Hole core hat life can be lengthened with careful maintenance, creating savings over time.

So, in conclusion hole core bit are one of a kind tools that can create holes with exactness and tidiness on different materials. When combining advanced technology with regular upkeep, this equipment can provide lasting performance at construction sites. Proper care and maintenance The selection of the correct bit for each task is important to ensure that construction projects move forward without a hitch on schedule. Hole core bits have a modest appearance, but their contributions in the sector of construction are immense that is suggestive of how important they really are when it comes to any kind of construction.

over 30,000 m2 factory space, modern equipment effective production lines, we able to guarantee quick response requests and supply high-quality goods with high cost-performance to our customers hole core bitthe world with efficient processes for production and stringent Q C guidelines.

developed strict Q C standards based years production experience. All of our products tested thoroughly prior to delivery, and include random inspection each process and quality control for every component of the key procedures. SGS certification for hole core bitand the international quality management system ISO09001 are both achieved. Each of the Guhua products are backed by MPA and CE safety certification.

Guhua's R D team consists of experts engineers, with over 20 hole core bitof experience the industry. We hold more than 40 patents, we are the leading company in the field for development, design and making brazed tools. This allows us create deep custom tools that can be used work with various hard materials which include brittle materials, as well as more complex, high-precision tools.

have over 20 years of international trading experience, working clients from more than 60 countries, now have local warehouses as well as subsidiaries located in the UK, India, Kenya. We can offer one-stop solutions to hole core bitworldwide, ranging starting from R D and production, to logistics after-sales services.

Our professional sales team are waiting for your consultation.

Copyright © Nanjing Guhua Electromechanical Technology Co., Ltd. All Rights Reserved | Privacy Policy