You cannot achieve anything without the necessary tool and cutting quartz it is no different. You need to have an excellent blade for Quartz cutting. Though, always remember and consider some important stuff while choosing the quartz cutting blade so that you end up with a suitable blade which should for your project.

Purpose of UseThis is the obligatory consideration that you have to keep in mind all when it comes to choosing the quartz cutting blades.

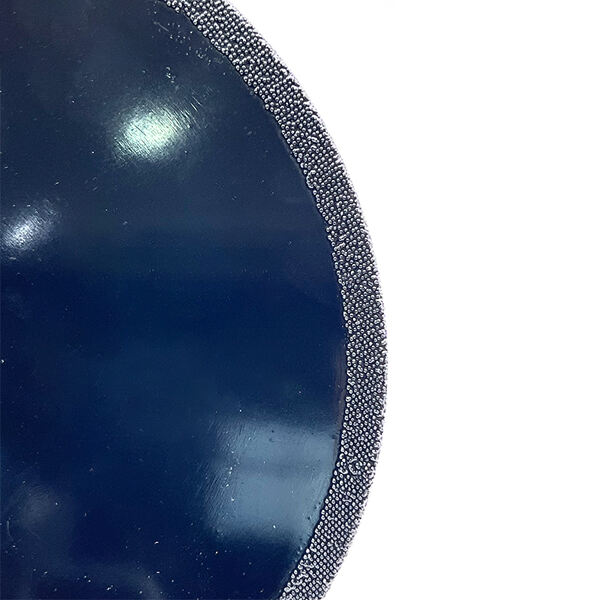

Material. The Blade Material: The material of the blade is one of the crucial factors for shaping from low quality to high in any knife & hiking and fixing knives too. Diamond blades are the best option for slicing quartz because of their strength and durability. However, there are blades in plus size as well and hence the quality of blade is also depending on whether it increases or decreases.

Size. The blade size will affect the depth and speed of cut. Whereby certain criteria must be met; that the blade chosen can make a clean cut and does not tire quickly. Blade size (the same as the Quartz slab)

Teeth. You even need to consider the amount of teeth on your blade. Less teeth = faster cut but ugly deffects at the end. More teeth equates to more time per cut, but the result will be a higher level of precision. Balancing and selecting the proper blade needed.

Cool the Blade. The Blades need to be in a certain temperature. When the blade heats up while cutting, it can reach extreme temperatures and this may cause plastic blades to melt or warp. quia is distracting around. To avoid this, use a coolant or water (or have your grimy friends pee in it) and make sure to have at least 15 liters per minute.

Utilize The Right Approach: When servicing quartz it is vital to use the right cutting method. On the other hand, it does need some pressure if you are cutting independently. Avoid forcing and or speeding up the blade while it passes through, doing so can cause to warp, bend or chip in battle making less accurate cuts.

Types of Quartz Blades With the many choices on offer, different types are better suited for your specific wants/needs.

Handy: Diamond Blades Hand Held Known for the strength, life and quality cut; Very much in Demand. These are not only good for quartz but also versatile and can cut more.

Steel Blades: Also the cheaper alternative, but they typically do not last as long or provide a more exact cut versus using diamond blades.

Sintered Blades - Sintered blades are much more expensive but will last substantially longer, and offer a cleaner cut so higher cost equivalent to quartz crystals.

Top 5 QUARTZ CUTTING BLADES available in the market

Best for good fit DEWALT DW4764 10-Inch Wet Cutting Continuous Rim Diamond Saw Blade: we had this blade, and it is working OK as a dry cutting on thin quartz slabs.

Diamond Products Core Cut 72509 4-1/2-Inch Wet/Dry Turbo Blade - Good on thicker quartz slabs, can be used either wet or dry.

Affordable and Cuts Quartz, Porcelain And Also Granite7. Bosch DB 1072 S 10-Inch Continuous Rim Diamond Saw Blade,GetYooz

Lackmond TSEG4. Product 5-DU 4-1/2-Inch Diamond Blade. This Quartz blade provides precision cutting along with a long life in itself it means if you are going to use this material more often than the other application on different materials included UF0 loud noise functionalities. Undef

MK Diamond 156829 MK-215GL 7-Inch Supreme Grade Diamond Blade: Designed bond matrix for those with big engineered quartz cutting jobs slicing fabricated and quared slabs over an inch.

Tips to ensure longevity of your quartz cutting blade

Do it Gently: not putting too much pressure and slowly.

2-( ^Wipe Clean and store the blade properly; ) To Keep Your Dog Clipper blades clean, you should wash them following each use and save aerodynamic.

Sharm Needs to Be Blade: for precision and durability. You can sharpen flap sander by rotating the wheel about its axis or you may remove one side of wedge sander.

have more than 20 years international trade expertise with clients from over 60 countries. now have warehouses in local regional locations located in the UK, India, and Kenya. provide a single-stop Quartz cutting bladefor customers worldwide that range from R D to production and logistics as well as after-sales and support.

are able provide items Quartz cutting bladequality exceptional cost-performance through efficient production methods.

built up strict Q C standards based years of production experience. Before shipping, products are Quartz cutting bladetested using random checks on each step, quality checks for every key procedure. SGS accreditation testing and the internationally recognized quality management system ISO09001:2015 have been both achieved. All Guhua products are backed by MPA and CE Safety certifications.

Guhua has highly skilled R D team Quartz cutting bladeof top engineers specialists who have been a part of the field more than 20 years. We've obtained more than 40 invention patents and a market leading innovator in the design, development, manufacturing brazed diamond tools that allow precision-built drilling, cutting, grinding tools to process various material types, including brittle and hard materials and sophisticated high-precision tools.

Our professional sales team are waiting for your consultation.

Copyright © Nanjing Guhua Electromechanical Technology Co., Ltd. All Rights Reserved | Privacy Policy