للوصول إلى العمق الكبير في الخرسانة، تحتاج إلى معدات حفر فعلية. هنا يأتي دور قطعة الحفر بقطر 200 مم. بمعنى آخر، يتطلب الأمر عملية قطع الحفر من خلال الأرض لإنشاء فتحة على شكل أسطوانة في المواد الخرسانية للأرضيات، مما يوفر فوائد الحفر دون الحاجة إلى أي سطح وضع (على سبيل المثال: الهياكل الصلبة مع الطوب) بمستوى جودة عالٍ.

تُعتبر قطعة الحفر بقطر 200 مم شائعة بشكل خاص في حفر الثقوب والأنابيب لأن هناك أحجامًا مختلفة لتطبيقات قطع الأنابيب. نستخدم هذه القطعة بقطر 8 بوصات للوظائف مثل حفر ثقوب عبر خطوط المياه والمواسير أو مع أنظمة التثبيت المعقدة المسبقة، مما يسمح بتوصيل الكهرباء والسباكة من خلال فتحة كبيرة تناسب التركيبات السكنية الجديدة.

لا يمكن التشديد بما يكفي على أهمية اختيار بت النواة المناسب، لأنه يمكن أن يعني الفرق بين مدى نجاح المشروع بالكامل. إليك بعض الضروريات التي تحتاج إلى مراعاتها عند اختيار بت النواة بقطر 200 ملم لفريق الحفر الخاص بك؛

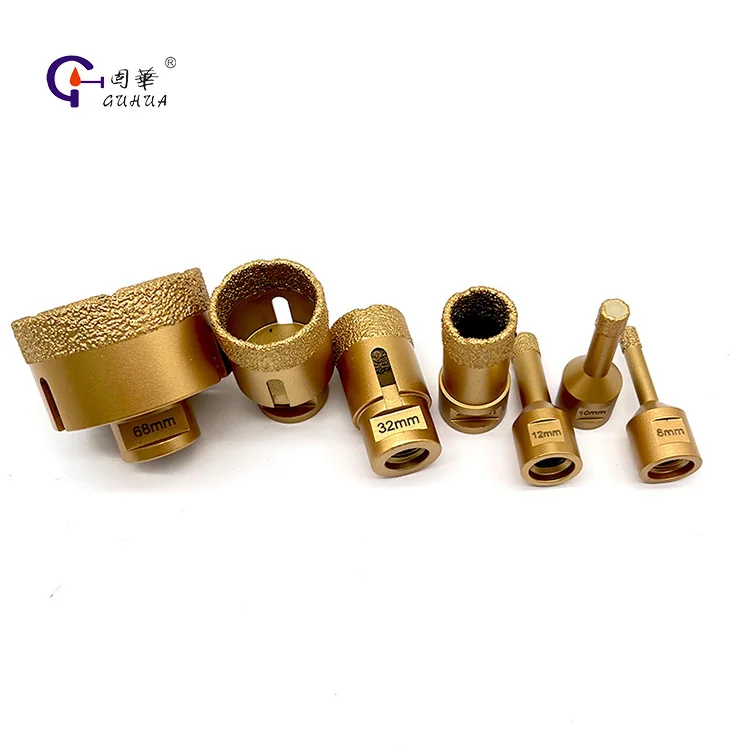

نوع المادة التي ستقوم بحفرها سيحدد نوع القطعة الأساسية التي يجب استخدامها. على سبيل المثال، ستحتاج إلى قطعة أساسية مطلية بالماس للأمور الأصعب مثل الجرانيت أو المواد الكثيفة جدًا، بينما قد يرغب شخص يقوم بالقطع في الطوب أو الخرسانة باستخدام قطعة أساسية مطلية بالكربيد.

التحدي الأخير وأحد التحديات الهامة هو أن الحرارة والاحتكاك الناتجين أثناء الحفر يمكن أن يضرّا بكل من القطعة الأساسية والسطح الذي يتم حفره. أفضل حل هو استخدام نظام تبريد بالماء لأنه يحايد حرارة القطعة الأساسية ويزيل الشوائب، مما يجعله وكيل تشحيم فعال للحفر.

طول القطعة: يجب أن يكون طول القطعة كافيًا لسمك الخشب، وإلا فإن القطع ستتعرض للاحتراق (أو أسوأ). القاعدة العامة هي أن الطول يجب أن يكون ضعف سمك المادة على الأقل.

أنا واثق أنك الآن تفهم أهمية العثور على أفضل مثقاب نواة مناسب لوظيفتك الحالية، وقد بدأت بالفعل في التفكير: أين يمكنني شراء هذا الشيء في أستراليا دون أن يكلفني ذراعًا وساقًا؟ هناك عدد كبير من المتاجر والمواقع الإلكترونية التي تقدم مثاقب النواة مع الأنابيب، لكن قلة منها توفر منتجات ذات جودة بأسعار معقولة. إليك بعض الإرشادات التي تساعدك على توفير المال والوقت للحصول على رؤوس ثقب بأقل من الأسعار السوقية:

قم بالبحث - قبل الشراء، اقضِ بعض الوقت في البحث عن العلامات التجارية المختلفة والأسعار. استكشف الأسواق الإلكترونية وحتى المتاجر الفعلية لمعرفة الأسعار والجودة!

نصائح: بالإضافة إلى ذلك، يمكنك سؤال أصدقائك وأقاربك أو زملائك في العمل الذين استخدموا رؤوس الثقب للحصول على بعض النصائح. قد يكون لدى بعض رؤوس الثقب معلومات عن بعض الموردين الذين يمكنهم شراء منتجات ذات جودة عالية وبأسعار معقولة.

الخصومات والعروض الخاصة: يمكنك حتى التحقق من العروض والخصومات عند شراء قطع النواة. المتاجر: معظمها تقدم الشحن المجاني فوق مبلغ معين، وخصومات تصل إلى 50% أو نحو ذلك. وضع فخ ButterKnife Tao. قد ترغب أيضًا في التفكير في الاستثمار في مجموعة من قطع النواة، وليس قطعة واحدة على حدة؛ سيكون ذلك أسهل على محفظتك.

عندما تحتاج إلى الحفر بشكل متكرر في مواد خشنة مثل الخرسانة والطوب، فمن الأفضل شراء قطعة نواة بقطر 200 مم. فوائد استثمارك في قطعة نواة بقطر 200 مم.

يمكن أن ت perform الحفارات المركزية الحفر بشكل أسرع وأكثر دقة مقارنة بأغلب الأدوات التقليدية الأخرى، مما يقلل من تكلفة العمالة في الحفر غير التدميري.

دقة حجم الثقب المحفور مع أدنى ضرر للمواد المحيطة يمكن أن تحققه قطعة نواة ذات جودة عالية ستتمكن من حفر ثقب بعد كامل بنفس القطر دون التسبب بأضرار للسطوح الأخرى المحيطة به، بشكل منتظم. وبالتالي تحصل على عدد كبير من الثقوب النظيفة بدون بروزات ويمكن استخدامها لخطوط الكهرباء أو المياه بمجرد إخراج حفارك اللاسلكي من الصندوق.

الاستمرارية: عادةً ما تُصنع هذه الأدوات من الماس أو الصلب، مما يجعلها فعلاً متينة للغاية (عادةً قطعة نواة بقطر 200 مم). عند الحفاظ عليها بشكل صحيح، يمكنها أن تدوم سنة بعد سنة... وهذا يجعل منها استثمارًا رائعًا.

المشكلة مع قطعة النواة بقطر 200 مم هي أنها تتطلب خبرة شديدة من جانب المشغل لتكون آمنة. إليك بعض النصائح المحترفة حول كيفية تشغيل قطعة النواة بقطر 200 مم بمهارة وأمان:

استخدام معدات الوقاية أمر ضروري (يجب ارتداء القفازات ونظارات السلامة والسدادات الصوتية أثناء استخدام قطع النواة لحماية العمال من التعرض لجسيمات الغبار الطائرة وتقليل الحوادث).

تبريد بالماء: احتفظ بتبريد البت الأساسي باستخدام نظام تبريد بالماء لزيادة滑 cutting surface وطرد الشظايا أثناء عملية الحفر.

هذا هو الخطوة الأساسية، وكل مصنع لبتات النواة سيكون لديه مجموعة خاصة من التعليمات حول كيفية استخدام بيته الخاصة بشكل صحيح وأمن. من المهم جداً اتباع هذه التعليمات بشكل صحيح، وإلا فقد يؤدي ذلك إلى الحوادث وتلف الأداة.

بت نواة بقطر 200 مم: إذا كنت ستقوم بحفر فتحات أكبر عبر الخرسانة والطوب وغيرها من المواد البناء الصلبة المشابهة، فإن بت النواة بقطر 200 مم هو ضرورة. ومع ذلك، يمكنك دائمًا اختيار البت المناسب وعدم الذهاب للخيارات ذات الميزانية الصديقة التي لا تزال آمنة ولكنها قادرة على خدمة مشاريع الحفر بكفاءة. ادخر المال الإضافي على بتات جيدة، اتبع دليل الشركة المصنعة ولا تنسَ أبدًا أن ترتدي الحماية stringently عند استخدام أجزاء حفر الخرسانة.

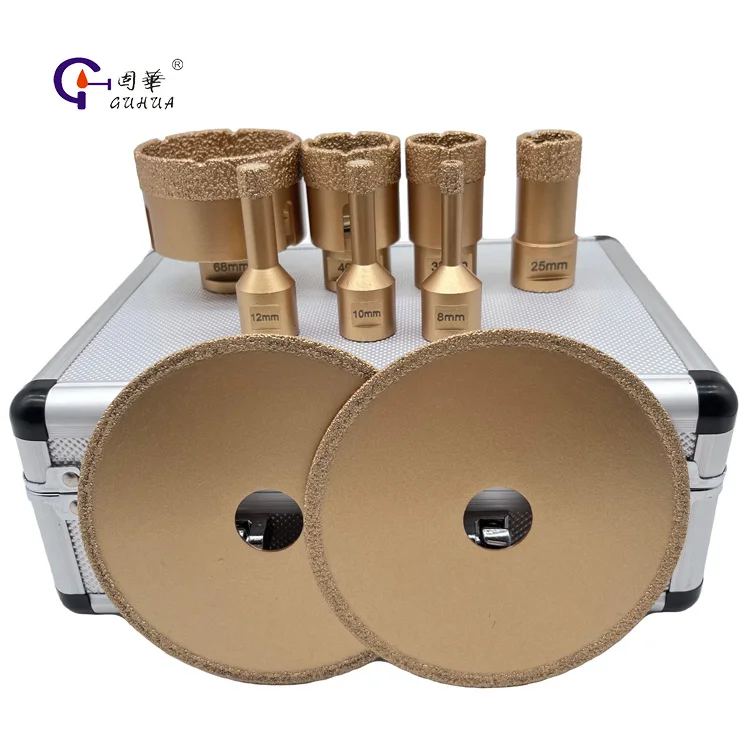

وبمساحة مصنع تزيد عن ٣٠٬٠٠٠ متر مربع، ومعدات حديثة، وخطوط إنتاج فعّالة لقاطع النواة بقطر ٢٠٠ مم، نحن قادرون على ضمان استجابات سريعة للطلبات وتوفير منتجات عالية الجودة وبتكلفة اقتصادية لعملائنا حول العالم من خلال عمليات إنتاج فعّالة وإرشادات صارمة لمراقبة الجودة.

لقد وضعت شركة غوهوا معايير صارمة لمراقبة الجودة استنادًا إلى سنوات الخبرة في الإنتاج. ويتم اختبار المنتجات بدقة شديدة قبل الشحن، ويشمل ذلك عمليات تفتيش دورية في كل مرحلة، بالإضافة إلى فحوصات جودة لكل مكوّن من مكونات إجراءات قاطع النواة بقطر ٢٠٠ مم. وقد حصلت الشركة على اعتماد شركة SGS للاختبارات، وكذلك نظام إدارة الجودة المعترف به دوليًّا ISO 9001:2015. وتحظى جميع منتجات غوهوا بشهادات السلامة الصادرة عن MPA وCE.

لدينا خبرة تزيد عن 20 عامًا في التجارة الدولية، وعملاء من أكثر من 60 دولة. ونمتلك حاليًّا شركات تابعة ومخازن محلية في المملكة المتحدة والهند وكينيا. وبذلك نستطيع تزويد العملاء في جميع أنحاء العالم بحلٍّ شاملٍ واحدٍ يشمل الأبحاث والتطوير وقاطعات الكور ذات القطر 200 مم، وكذلك الخدمات اللوجستية ودعم ما بعد البيع.

تضم شركة غوهوا مهندسين وخبراء أكفاء في مجال الأبحاث والتطوير وقاطعات الكور ذات القطر 200 مم، وقد أمضى هؤلاء الخبراء أكثر من 20 عامًا في هذا القطاع. وحصلنا على أكثر من 40 براءة اختراع، ونُعتبر الرائد العالمي في تصميم وتطوير وإنتاج أدوات الألماس الملحومة، مما يمكّننا من تصنيع معدات الحفر والقطع والطحن بدقة عالية لمعالجة مختلف المواد الصلبة الهشة والمنتجات المعقدة عالية الدقة.

فريق المبيعات المحترف لدينا ينتظر استشارتك.

حقوق النشر © شركة نانجينغ غوهوا للتكنولوجيا الكهروميكانيكية المحدودة. جميع الحقوق محفوظة | سياسة الخصوصية