In core drill bits, nano-enhanced coatings are crucial to ensure the long life of these devices. These coatings use nano-particles, the tiny particles, to coat the drill bits so they do not get damaged early. In the following article, we will discuss how nano-technology will keep your core bits strong and lasting long.

The Effect Of Nano-Enhanced Coatings On Core Drills

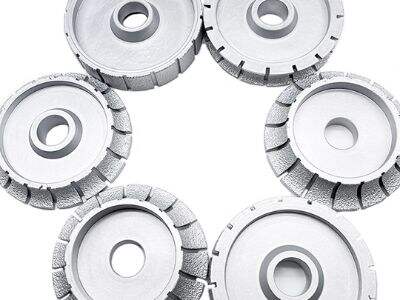

Ever wondered how core drill bits can cut through tough materials — such as metal and concrete — without busting? Nano-enhanced coatings are the secret. These are placed on the core drill bit surface to harden it and provide resistance against damage. These coatings form a protective barrier, using nano-particles, that allow the drill bit to last longer and work better.

How Nano-Tech Extends the Life of Core Drill Bits

Nanotechnology is a form of new technology that works with materials on a very tiny scale. With nano-particles in the coatings, core bits can take more pressure and friction while drilling. That means they can last longer and work more efficiently, saving time and money for users. Nanotechnology ensures that core bits remain effective and strong for much longer than most other core bits.

Protecting Core Drill Bits From Wear and Tear Using Nano-Coatings

Core drill bits are frequently employed in harsh environments that are generally conducive to quick wear and tear. Thanks to nano-enhanced coatings, wear on the drill bits is outperformed as well. The nano-particles of the coatings form a layer with high density, the slight porosity in the layer possses cushion effect to the bits when drilling, so as to protect the bits for normal working. This means core bits deliver even longer life and better performance when drilling in the toughest drilling conditions.

Advantages of Utilizing Nano-enhanced Coatings for Core Drill Bits

There are several advantages of using nano-coated on core drill bits. They not only help extend the life of drill bits, but they also help them work better. Nano-coatings make the core drill bit stronger, more capable of resisting heat and friction, and less likely to chip or break while drilling. So you can rely on your drill bits to get the job done right without having to replace or repair them frequently.

how nano-coating is revolutionizing the Core Drill Bits Lifespan

Thanks to nano technology, core drill bits are now better than ever and are designed to last longer as well. Drill bits are getting an upgrade with nano-enhanced coatings, which make them stronger, more durable, and more efficient. Core drill bits are able to reduce the risk of harder drilling situations while still function decent every time by these unique coatings. The benefit to these features is, it gives users to finish there drilling jobs fast and effectively.

In Conclusion

Core Drill Bits & Nano TechnologyBeing able to remove the same amount of material as standard core drill bits and take substantially longer to wear out: what you need to know about new nano enhanced core drill bits.About Nano-Enhanced CoatingsNano-enhanced materials provide superior means to protect metal materials against corrosion, preventing wear and abrasion by sound construct protected and finished products. These coatings protect drill bits so they can last longer, giving high performance by use of nano-technology. Such as through the use of nano-coatings, core drill bits may perform better and have a longer life for the user. GUHUA leads the way in technology by producing quality impregnated diamond bits with nanoenhanced coatings that have begun to revolutionize the drilling industry.

Table of Contents

- The Effect Of Nano-Enhanced Coatings On Core Drills

- How Nano-Tech Extends the Life of Core Drill Bits

- Protecting Core Drill Bits From Wear and Tear Using Nano-Coatings

- Advantages of Utilizing Nano-enhanced Coatings for Core Drill Bits

- how nano-coating is revolutionizing the Core Drill Bits Lifespan

- In Conclusion

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW