Choisissez la bonne lame diamantée pour granite pour votre travail de construction

Une lame diamantée pour le granit est tout aussi cruciale pour l'industrie de la construction, oh que je puisse plaisanter (l'humour mordant est sérieux ici) ! Le granit = une sorte de roche naturelle normalement utilisée dans les travaux de construction, ou des matériaux très solides (pensez à MacGyver installant une barrière entre lui et les méchants qui essaient de rivaliser avec son intelligence pour contrôler le monde).

3 choses à rechercher lors de l'achat d'une lame diamantée pour le granit pour un découpage haute vitesse : Une lame diamantée pour le granit est l'un des meilleurs investissements que vous puissiez faire lorsque le découpage de votre plan de travail en granit utilisé commercialement est nécessaire...

Lors du choix de la bonne lame diamantée pour le granit pour un découpage haute vitesse, plusieurs facteurs cruciaux doivent être pris en compte. Ces éléments déterminent considérablement la performance d'une lame ; ou cliquez sur ce lien si vous N'ÊTES PAS au Royaume-Uni.

La profondeur de coupe est également le résultat de cette lame et de son diamètre. En général : Sélectionnez des lames de 4 pouces ou moins *Pour les gros travaux - optez pour plus d'un demi-pouce

La lame déterminera sa performance et elle varie en fonction du liant utilisé. Si l'élément à couper n'est pas dur, vous pouvez travailler plus rapidement en utilisant un type de liant doux pour résoudre votre problème, mais pour couper des matériaux plus durs, il faut des lames diamantées avec des liants solides.

Les derniers points à considérer concernant les lames diamantées sont la taille des particules et la granulosité de leurs diamants. Les numéros de grains élevés sont idéaux pour le découpage du granite, car ils coupent plus finement.

Comment choisir votre lame de scie diamantée pour le granite.

N'oubliez pas de choisir la lame diamantée pour granite la plus appropriée pour votre nouveau projet, car c'est essentiel pour obtenir des résultats optimaux. Voici quelques accessoires importants à prendre en compte pour sélectionner la meilleure lame avec laquelle vous allez couper :

Taille de la plaque de granite

Lorsque vous obtenez une plaque de granit pour un découpage approprié, assurez-vous que la lame diamantée est capable de faire des coupes selon vos souhaits. Les plaques plus épaisses nécessitent des lames diamantées segmentées de grande taille pour permettre une vitesse de coupe optimale et une précision maximale.

Type de granit à couper :

Oui, mais tous les granits ne sont pas égaux, donc il faut également rechercher une lame adaptée à l'utilisation prévue. Vous aurez besoin de lames avec des liants légers pour couper le granit doux plus facilement, mais vous aurez également besoin de particules de diamant en plus grande quantité.

Coupe humide ou sèche :

Le deuxième facteur important est le type de matériau que vous allez découper avec une lame diamantée (coupe humide, sèche ou les deux). Bien que la coupe humide soit généralement efficace et propre, certains projets qui ne permettent pas l'ajout d'eau seront souvent mieux servis par la méthode de coupe sèche.

Lame diamantée pour granit vs. autres types de lames :

Parmi les types de lames effectuant des tâches de coupe lourdes, la lame diamantée offre une grande force et une fonctionnalité durable, ce qui en fait une option plus précise que d'autres outils. Si vous êtes un utilisateur régulier de lames, elle peut se détériorer après 5 à 6 mois. Même les lames carbure les plus durables ne peuvent fournir autant de précision en coupe qu'une lame diamantée.

Meilleures Lames Diamantées 1. Rendre la Coupe du Granit Facile

Nous avons préparé quelques exemples des meilleures lames diamantées qui simplifieront tout lorsqu'il s'agit de couper du granit.

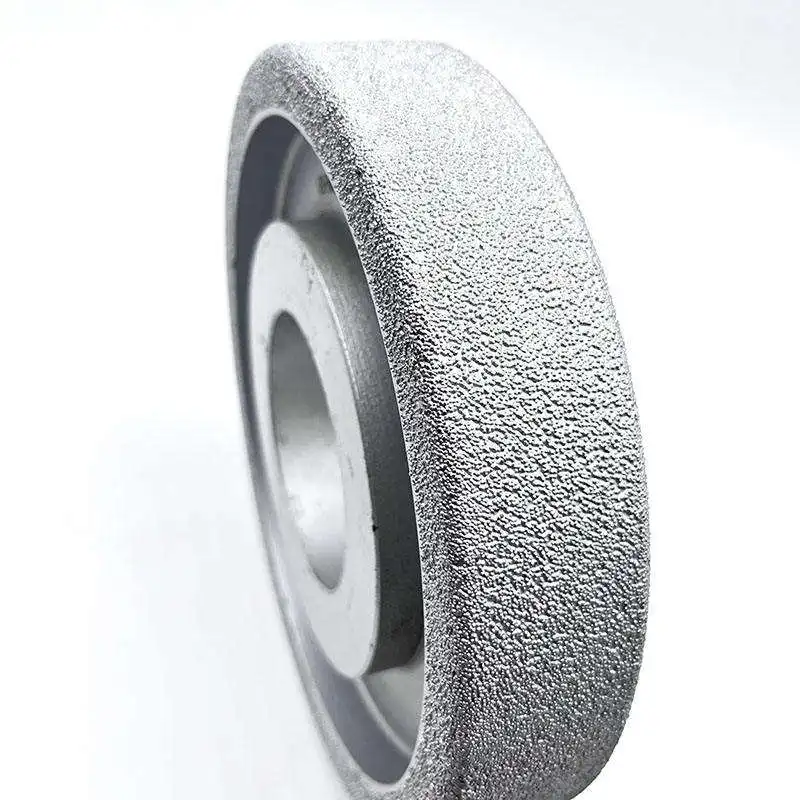

Matériau 012 - Lame Diamantée à Bord Turbo --3I- Le design turbo permet une coupe rapide et plus douce.

Outil à Eau Idéal pour les Grands Plaques de Granit avec Lame de Pont

Lame Diamantée Segmentée ~ La meilleure méthode pour couper des plans de travail en granit avec un minimum de poussière.

Les Choses à Faire et à Ne Pas Faire Concernant le Recyclage

L'utilisation efficace d'une lame diamantée pour le granit n'est pas aussi simple, en raison des compétences techniques nécessaires. Voici quelques conseils rapides pour en tirer le meilleur parti [collapse]

Installation correcte de la lame :

Installée correctement, c'est-à-dire mesurée précisément pour respecter les lignes directrices de sécurité de la scie contre les accidents qui pourraient entraîner un mauvais découpage ;

Précautions avant et pendant le découpage humide pour éviter surchauffe des lames (les tuyaux sont pour rinçage, pas pour refroidir !)

Optimisation du découpage sec :

Pour le découpage sec, vous lubrifiez la lame diamantée avec de l'eau et effectuez des coupes en tenant compte de sa capacité limitée à maintenir la précision lors du découpage.

Ainsi, choisissez la lame diamantée adaptée au granite pour obtenir la meilleure précision, vitesse et longévité lors du découpage de matériaux durs comme le granite. Vous pouvez sélectionner la lame appropriée selon votre projet en considérant l'épaisseur de la lame, le type de granite et la largeur de votre grille diamantée. hexfly(fc3ecc) ; En suivant ces conseils et en utilisant ces techniques, l'utilisation d'une lame diamantée pour granite sera très simple.

Nous opérons sur le marché international depuis plus de 20 ans. Nous avons des clients dans plus de 60 pays différents. Nous disposons de bureaux locaux et de magasins au diamant sur granit au Royaume-Uni, en Inde ainsi qu'au Kenya. Nous sommes en mesure d'offrir une solution clé en main à nos clients mondiaux, couvrant la recherche et développement, la production, la logistique et le service après-vente.

sont en mesure de livrer des produits de haute qualité, des lames diamantées pour granit offrant un excellent rapport coût-performance grâce à nos méthodes de production efficaces.

a établi des normes strictes de contrôle qualité fondées sur des années d'expérience en production. Avant expédition, les produits sont testés au diamant sur granit, avec des contrôles aléatoires à chaque étape et des vérifications de qualité pour chaque procédure clé. L'entreprise a obtenu la certification SGS ainsi que le système de management de la qualité reconnu internationalement ISO 9001:2015. Tous les produits Guhua sont garantis par les certifications MPA et CE Safety.

L'équipe Recherche et Développement de Guhua est composée d'ingénieurs experts possédant plus de 20 ans d'expérience dans le domaine des lames diamantées pour granit. Nous détenons plus de 40 brevets et sommes leaders dans l'industrie en matière de développement, de conception et de fabrication d'outils brasés. Cela nous permet de concevoir des outils profondément personnalisés, adaptés au traitement d'une grande variété de matériaux, y compris des matériaux fragiles ainsi que des pièces plus complexes et de précision.

Notre équipe de vente professionnelle attend votre consultation.

Droits d'auteur © Nanjing Guhua Electromechanical Technology Co., Ltd. Tous droits réservés | Politique de confidentialité