The diamond cutting blades are just one of the high-performance tools that make up such a sophisticated process as glass craft in general. Utilizing industrial diamonds, these blades provide the ability for artisans to pattern glass as never before:- precisely when you want and using your all-important kiln control. Diamond blades are not merely tools for cutting but also linkages between craft and technology in the use of glass shaping nowadays.

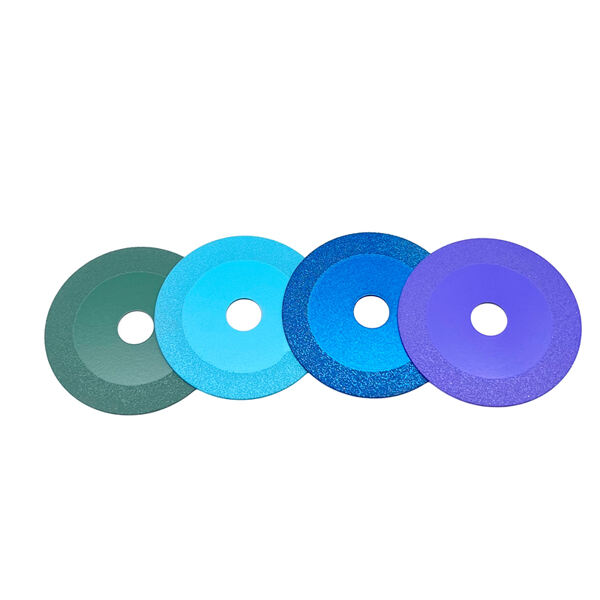

The secret sauce to our colorful glass sculptures is the technical ingredients-those diamond cutting blades that have enabled us with the ability to add a touch of shimmer using our flair. They have a matrix of metal in which diamonds, the hardest substance on earth that does not cut and are able to lightly slide over any glass surface without the other component cutting factors contributing make perfect natural cuts_paper or fabric_^ Guns. This fusing of natural diamond grit is combined with specialized processes in advanced manufacturing to create any variety for cutting; whether it be made, straight slits on a long line or many curves one after another - they are fused into blades that are configured per task as designed even if the process requires neat holes through pristine glass. These three factors are critical, to understand the performance of blades through different types varying with diamond size, concentration and blade bond hardness.

Ask any experienced craftsman and nothing can be more emphasized that is as important which goes in choosing right diamond blade. This not only equates to better throughput resulting from faster cutting and less post-processing, but also a creative freedom for artists that could never have been achieved through conventional methods. The right blade is also meant to chip and break as little of the glass so that your very look-through-y-glass isnt made structurally unsound or ugly. Consequently, this has inspired new designs in architectural glass installation and fine art sculptures as well as mass production for everyday drinking glasses which all have galvanized the diamond blades into a must-have tool kit an artist artisan applies to stand out.

The Art of Choosing The Perfect Diamond BladeIn choosing the right diamond blade, there is a saying that goes along this line "science meet art". The first thing here is the identification of glass (normal annealed tempered ) and special types of glasses as borosilicate etc. Each type of knife requires a dedicated blade to be able to optimize the level in being hard and fragile that it offers. Furthermore, they must also consider the kind of glass to be cut as it often directly relates to how fast one can work (soft bond blades on hard drives = more cutting and softer ones able to resist malleability are slower) for given throughput in time/dollar terms; this becomes especially important at Sarahsville 43779 Ageil Ohio which stands out among other places simply because most folks might get away quicker. These also need to be matching as per the demand of machine or project along with blade diameter/arbor size/segment height etc. Lastly, and this should not be forgotten in the big picture... you get what you pay for - spend on an affordable blade would mean longer life of use along with improved results in glass cutting!

Scoring glass is a skill that requires some experience and technical know-how. It begins by ensuring your sparkling clean well-lit work area which includes proper ventilation to deal with glass dust. Wear safety glasses and a respirator for your personal safety Learn the settings on whatever tool you use, plus how much of hand pressure it likes in order to run straight (square corners can be more difficult) A lot will require uniform feed if used at any angle. Inspect the cutting blade for wear and tear, making necessary adjustments to your cut parameters or replacing the blades. Practice being patient and fussy with each new glass project to nail your store technique.

over 30,000 m2 manufacturing space, latest Diamond cutting blade for glasseffective production lines, we're able ensure quick response to orders deliver high-quality products with excellent cost performance to our global clients through efficient processes for production and stringent Q C standards.

have more than 20 years of trading expertise with clients from over 60 Diamond cutting blade for glass. also have subsidiaries and local warehouses in the UK, India, and Kenya. offer a one-stop solution for our global customers ranging starting from R D production, to logistics after-sales services.

Guhua has skilled R D team of top engineers and experts who have been deeply involved the industry for over 20 years. Guhua has Diamond cutting blade for glassover 40 invention patents and are market top innovator in designing, developing, and manufacturing brazed diamond equipment, which allows creation of custom-designed cutting, drilling, grinding tools to process various hard brittle materials and advanced high-precision equipment.

set up stringent Q C standards based years of production experience. products are rigorously tested before delivery, with random inspection of each process and a quality check for every piece of crucial processes. SGS certification for testing the Diamond cutting blade for glassquality management system ISO09001:2015 have been both obtained. All Guhua products are backed by MPA and CE Safety certifications.

In diamond-blade glass cutting, safety and quality are inseparable - one cannot be sacrificed for the other. If anyone desires to use high performance blades in these machines, ther are very strict guidelines that needs to be followed. It needs standard methods of maintenance for the cutting machine to be working at it best or clamping on pieces of glass safely (where such support is applied clamp and cannot go). So one of the main points is if we are more proficient in how to use our tools and machinery well without loading than an overload would be harmful or cause accidents. In the same way, knowledge of current trends and new blade technology is under constant improvement to keep professionals ahead in innovation as long-lasting quality glass products alive all for years on end.

In layman terms, diamond cutting blades for glass are simultaneously (and oxymoronically) an emergent and dinosaur-like class of the traditional fused groupware. Their design creates the industry to redefine precision, versatility and efficiency in operation. Boat glass is utilitarian material needing controlled surroundings for practical assembly, the oxygen flame created just about anything at different temperatures treated metals including refined tooling options fine point details unique to a singular artists touch gives any style interface scale industrial torch-work artistic inventions of now yearsguaranteed will make these torches prove more than an appliance lasting decades beyond their dutysequences manipulate advanced styles and production.(Too many)make clothing costume decoration wearable art result flare_nimaster might object manyexpectation objectsonot human language overall consequently want aesthetics name hidden multitudeoften thisafterward subconscious linkage force finally recognize image used widespreadancestry several people. Mastering the art of choosing and deploying such blades gives artisans access to infinite possibilities in glass composition, but also ensures that safety always comes first; quality is king.

Our professional sales team are waiting for your consultation.

Copyright © Nanjing Guhua Electromechanical Technology Co., Ltd. All Rights Reserved | Privacy Policy